Layout of a Knit Composite Factory

1 : Security office. (factory layout)

2 : Administration office

3 : Fabrics Store (Gr.Floor)+Knitting (2ndFloor+3rd floor), . . Human Resources Department (HRD)(4thFloor), . Marchanding section (5thFloor), garments(6th Floor – 9th floor)

4 : Yarn store (Gr. Floor)+ +Garment section(1st Floor – 7th floor)

5 : Knit Fabric dyeing & finishing section.

6 : Effluent Treatment Plant (ETP).

7 : Generator house, Water Treatment Plant(WPT), Maintenance building.

Lay-out Of Dyeing & Finishing Section:

- Office of PM

- Offline QC

- Inspection table

- Compactor

- Tube-tex

- Equalizer Dryer

- Steenter

- Calender

- Slitting m/c

- Squzzer m/c

- Office of GM

- Chemical store

- Dilmelner high pressure Dyeing m/c

- Office & Online QC

- Bangla dyeing m/c

- Korean dyeing m/c

- Sample dyeing m/c

- Turning m/c

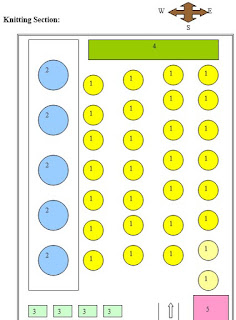

Knitting factory layout:

1. Circular knitting m/c

2. Auto stripe M/c

3. Flatber m/c

4. AGM & stuff (Knitting)

5. Store

0 Comments on "A Basic Layout of a Knit Composite Factory "